Installation instructions ADA commercial motion sensor faucets

ADA Commercial Motion Sensor Faucets Installation Instructions

The hands free ADA commercial motion sensor faucets have the body made of solid brass, a high strength material that protects against erosion and abrasion. They come in different finishes like chrome, oil rubbed bronze or gold plated finish. These sensor faucets are ADA compliant and fit for residential or commercial use.

Prior to installation

Before installing the sensor faucet, please open the box to check whether it includes all the items on the packing list.

Installing Sensor Faucet

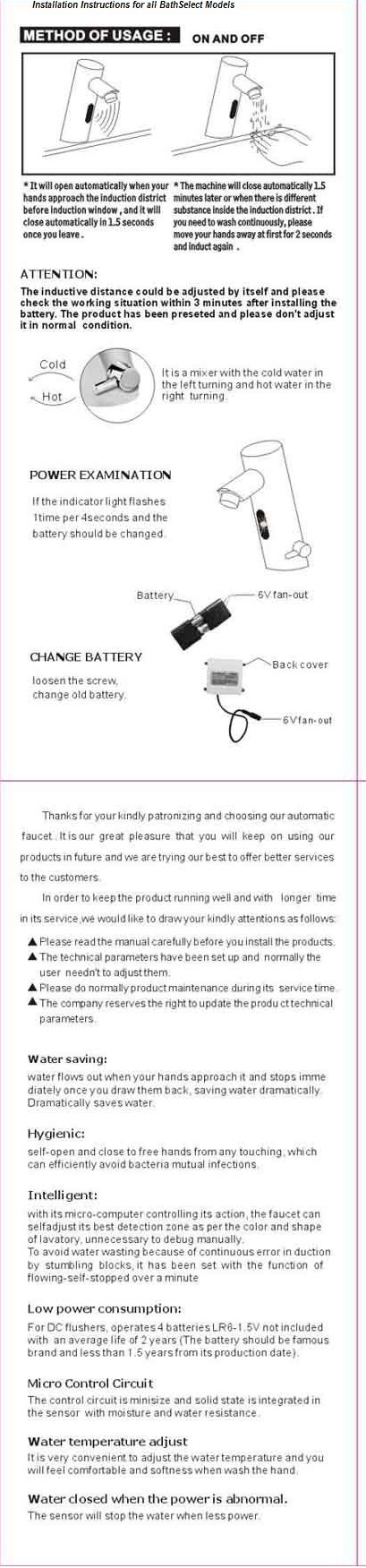

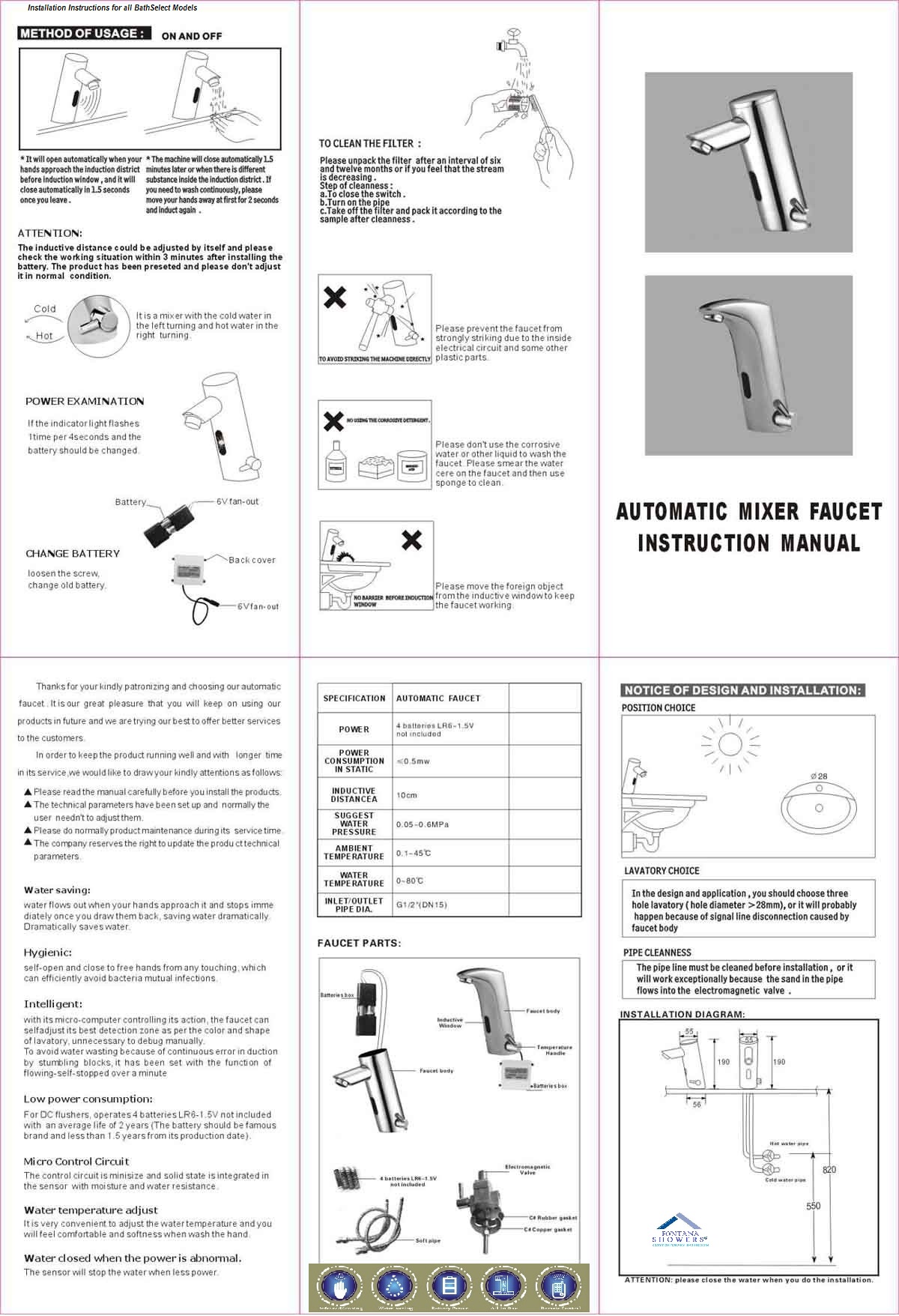

Please install touchless sink faucet as per installation instruction. Note: We don’t supply the inlet pipe. Before installing Control module assembly, please check your inlet pipe whether it can be connected to the deck.Please shut off the water valve of inlet pipe before installation. Please check whether detection zone factory set as “SPECIFICATION” meets your requirements; otherwise please adjust it according to your requirement. The steps are as follows:

Adjustment of sensor distance

Loosen the 600 mm flex hose deasil from faucet assembly. Loosen the two nuts under the base gasket using a head screwdriver, please push the “sensor eye” slightly and take it out. Loosen the six nuts from the control module assembly, open and take out the battery compartment, put 4AA alkaline batteries into battery compartment. Connect fiber optic cable to the battery compartment. (Note: When connecting optic cable to battery, do not keep the sensor object near the sensor location). Please use your hand to approach the “sensor eye” slowly from exceeding 30 cm.

When your hand is in the sensor location, you will hear a beep from the battery compartment, meanwhile, the LED in the “sensor eye” will flash red. A small nut is on the chipset located on the basis of “sensor eye”, turn around this small nut anti-clockwise to increase or shorten the sensor distance. When the adjustment is finished please take off the fiber optic cable from the battery compartment, also take out the batteries. Put the “sensor eye” into the faucet assembly, put the faucet assembly together with the fiber optic cable through the holes into the base of trim plate without border & base gasket, and then screw the two nuts of the gasket.

Connect the flex hose to the basis of the spout

(direction towards without nut). Screw the two studs into trim plate with head screwdriver. Put two (2) fender washers on the holes on top of deck which for inserting the two studs. Insert the faucet assembly and the fiber optic cable together with the flex hose and studs through holes in deck. Using two (2) fender washers into the two studs from below deck, and then put two (2) finger nuts supplied into two studs, screw them into studs from below deck to secure trim plate on deck.

Install Control module assembly

Before installing Control module assembly, please check the place of deck and installation place of Control module assembly. If confirmed, please put the Control module assembly onto the wall first, and use drill bit to anchor the four holes. (Figure 4 Control module assembly)

- Using ø 6 mm drill bit follow the four anchors to drill four holes into wall.

- Using a hammer knock the four plastic wall anchors supplied into wall.

- Installing Control module assembly to wall, knock four self–tapping screws into four plastic wall anchors. Then the Control module assembly is installed onto wall.

Connect flex hose to solenoid valve

Use a wrench to connect the free end of the flex hose to the outlet side of the solenoid valve.

Connect fiber optic cable

- Connect the free end of fiber optic cable to the Control module assembly.

- Thread the connector cap with nut onto the Control module assembly to secure the connection. Note: Please keep the sensor plastic cable clean and dry when install it, in order to keep the machine workable. Note: When installation is finished, please use a small piece of soft and dry cloth to wipe away the “sensor eye” slightly.

Battery installation

Note – DO NOT INSTALL THE BATTERIES UNTIL THE FAUCET IS COMPLETELY INSTALLED. If the batteries are installed before the fiber optic cable has been connected to the Control module assembly, the faucet will not properly set the sensing range for the sink on which it has been installed. Loosen the cap of control module assembly with head screwdriver, and loosen the cap of battery compartment. To ensure proper operation, inset four (4) new C-size alkaline batteries.

Check that the orientation of each battery matches the positive (+) and negative (-) symbols shown in the bottom of the battery compartment. Make sure that spout is properly centered and that no objects are in the sink. Close the cap of battery compartment and cap of the control module assembly follow the above steps.

Connect inlet pipe

Please connect inlet pipe to control module assembly. Note: Please use the proper inlet pipe into diameter of inlet on solenoid valve. Very important: Please turn off the inlet pipe valve to install the inlet pipe.

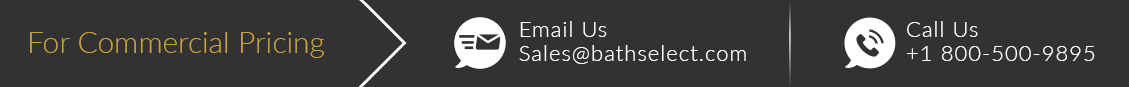

Turn on the inlet pipe valve

Please turn on the inlet pipe valve, to check whether water flowing and sensor distance meets your requirements. If not, please follow the above ways to adjust the sensor distance again.

BATTERY REPLACEMENT PROCEDURE Battery powered faucet with 4AA alkaline batteries can be used for 2 years at 200 cycles a day. When the batteries are low and need to be replaced, the faucet will signal you, when your hand approach the sensor location, the LED will flash red three times quickly without water out; when without object to approach the sensor location, the LED will red one time per four second. At this point we recommend battery replacement.

Note – Water supply to the faucet does not need to be turned off when replacing batteries. Loosen the cap of control module assembly with a head screwdriver, and loosen the cap of battery compartment. To ensure proper operation, inset four (4) new C-size alkaline batteries. Check that the orientation of each battery matches the positive (+) and negative (-) symbols shown in the bottom of the battery compartment. Make sure that spout is properly centered and that no objects are in the sink. Close the cap of the battery compartment and cap of the control module assembly, follow the above steps. Upon installation of the batteries, faucet will begin a new self calibration procedure.

SOLENOID SCREEN FILTER CLEANING PROCEDURE Before cleaning the screen filter, turn off the water supply at the supply stop(s). Turn off the inlet pipe. Activate the faucet to relieve any pressure in the system. Clean the screen filter using fresh tap water. If necessary, use a small brush to clean. Use caution while cleaning to prevent damage to the solenoid screen filter. Connect the inlet pipe; turn on the water supply at the supply stop(s). Activate the faucet to purge any air from the system lines. Check for leaks and repair as necessary.

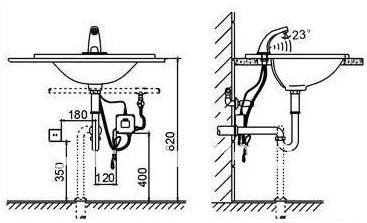

| SPECIFICATIONS of Battery Powered Faucet | |

| Diameter of inlet pipe: | G(1/2)” |

| Diameter of outlet pipe: | G(1/2)” |

| Water pressure: | 0.05Mpa-0.6Mpa |

| Power and voltage: | DC6V |

| Power Consumption: | 0.5MW |

| Ambient temperature: | 0.1-45°C |

| Detection Zone: | Factory set 20CM for HD-501DC, HD-507DC

Factory set 25CM for HD-502DC Factory set 17CM for HD-506DC (Based on standard inductive board) |

| Protection degree: | IP56 |

| Sensor Faucet Packing List Installation instruction | one copy |

| Faucet and sensor assembly (including trim plate with chrome and 800MM fiber optic cable) | one piece |

| Trim plate 162.5X65mm | one piece |

| Finger nuts ø 10mm | two pieces |

| Studs ø 10X45mm | two pieces |

| Washer gaskets | two pieces |

| Base gasket | one piece |

| Solenoid valve module assembly for battery powered model (including solenoid enclosure, solenoid body, and battery compartment). | one piece |

| Flex hose (Length: 600mm) | one piece |

| Screws M3X8mm | six pieces |

| Self-tapping screw M3X17mm | four pieces |

| Plastic wall anchors ø7X27mm | four pieces |

Operation:

- Place hands under spout and directly in front of the neck mounted sensor, water will begin to flow out in less than a second. Water flow rate is governed by aerator and supply pressure, water temperature is governed by position of water mixture selector, as well as water temperature in supply pipes. Please remember, automatic faucets employ”presence” not “motion” sensors. An idle object placed directly underneath spout will immediately activate faucet.

- Remove hands, water will cease to flow within 1-3 seconds.

- If hands are left underneath the spout for more than 60 seconds, water will automatically shut off. To initiate flow again move hands away from faucet and start at step 1.

- When attempting to run water over small objects such as tooth brush, it may be necessary to bring the object closer to the sensor to initiate water flow. When water begins to flow, move object back under stream of water. Once user “gets the feel” of the faucet this step may be skipped.

- Faucets with water mixture selector above the sink. Water mixture ratio is adjusted from hot to cold and anywhere in between by moving lever.

Battery Replacement Instructions –

Batteries should provide 12 to 36 months of reliable service mostly depending on the make of battery used and the frequency of usage among other factors. Battery weakness is indicated by constantly flashing led light within the sensor capsule. When replacing batteries please follow these simple steps:

- Unplug battery from faucet.

- Unfasten the 4 Philips screws that hold the enclosure cover on, pull enclosure cover off.

- Replace batteries with 4 AA Alkaline batteries, make sure batteries are placed in their proper position.

- Re-install battery pack into the Faucet.

- Test faucet prior to placing enclosure cover back on.

Troubleshooting –

Faucet does not operate, red light does not blink –

- Batteries need replacing – replace batteries, see battery replacement instructions.

- Sensor wire loose, unplugged, plugged improperly – plug sensor wire properly. See installation instructions.

Water flows out of faucet even though hands or objects are not present under spout –

- Objects (such as sink lip) are present in front of sensor. (See special installation note at the back page).

- Battery wire not plugged in, batteries need replacing.

Faucet does not operate, red light blinks in response to approaching objects –

- No water, very low water pressure in supply pipes, supply valves closed.

- Water pressure very high, well above 115 PSI.

- Screen filter severely clogged up.

- Supply hoses severely kinked.

Faucet leaks, drips –

Constant leaks or drips indicate defective solenoid valve, send Faucet Automator for repair or contact an authorized plumbing professional.Faucet continues to run for 30 -60 seconds after hands are removed

This very rare condition generally occurs due to over sensitivity on the part of the sensor, system water pressure well above 70psi and an over lit bathroom environment. This condition is always field curable.

- Turn down water pressure at both angle stops.

- Adjust sensor range. See Sensor Range Adjustment in this manual.

- Objects (such as sink lip) are present in front of sensor. (See special installation note at the back page).

LIMITED WARRANTY

BathSelect warrant this faucet to be free of defects for a period of one year from date of purchase. BathSelect will replace, free of charge, during this warranty period, parts that prove defective when properly installed and under normal use and service. Damage that occurs as a result of abuse,improper installation, environmental conditions, or improper application will void this warranty. Products must be shipped with postage and handling prepaid, along with dated proof of purchase. This warranty does not cover installation or any other labor charges. it does not cover shipping and handling of both replacement parts and returned defective parts. Products or components that have been altered or in any way modified will not be covered under this warranty. Replacement parts are under warranty only for the remaining period under the initial warranty. Some states do not allow for exclusion of incidental or consequential damage.

Special Installation Note Automatic faucets are design to perform properly in a variety of applications. There are some conditions, however, that may adversely impact the faucet’s ability to perform. Please note the following conditions prior to installing you new faucet –

- Your automatic faucet is designed for indoor applications. This faucet is not designed for outdoor applications.

- Avoid installing your new faucet in direct sunlight. Direct sunlight that is focused on sensor will temporarily disable faucet’s sensing capabilities.

- When installing your faucet to your counter top please view the drawing below and read accompanying note.

- When choosing a location to install the Faucet Automator, make sure that it will not be in direct contact of copious amounts of water.

- If you choose to install your faucet to one water source only, do not install to hot water only as this may result in scalding injury.

See also

- Basic tools needed for Installing Sensor Faucet

- Sensor Faucet Frequently Asked Question – FAQ

- Commercial Sensor Faucets

- ADA Handsfree Touchless Sensor Faucet compliance guide

According to Title III of the Americans with Disabilities Act (ADA) it requires all public accommodations constructed after 1990 be accessible to disabled citizens. In addition to barrier-free access to the building itself, fixtures such as faucets must also be accessible. Further, operation of the faucet must not require tight pinching, grasping or twisting of the wrist. The force to activate the faucet must be 5 lbs. or less. Hand-operated faucets must remain open for at least 10 seconds. Lever Operated: sensor faucet commercial Lever operated controls are ADA compliant if they meet the 5 lb. or less force requirement FAQ Sensor Faucets

Touch Free Easy Activation

The Infrared-controlled and capacitive-sensor controlled faucets are the most universal, offering user’s touch-free, easy activation. In general the ADA Accessibility Guidelines means Faucets need to be lever, push-type, or electronically controlled operating mechanisms. In the event that a faucet is self-closing, such as a metering faucet, the faucet must remain open and running for at least 10 seconds. The commercial sensor faucet at Bath Select meets the ADA requirements. Many options are available for attractive and user-friendly. Lever controls are also easy to operate with one hand.

Advantages

Push-Type – ADA compliant push-type faucets are economical because they allow water to run for a limited amount of time. Because it may take more time and effort for a disabled person to wash, however, push-type faucets may be inconvenient. Electronically Controlled: Infrared-controlled or capacitive-sensor faucets are ADA compliant, easy to use and especially sanitary for all users. Those motion detection sensors are innovative, durable and stylish and designed to operate in the toughest commercial applications. They are energy efficient and reduce the chance of flooding. Hand Washing sensor bath filler taps are also available in tempered or hot/cold water operation, see our line at Bath Select for commercial sensor faucets.

Sensor Faucets SPECIFICATIONS –

Here are most FAQs that are asked by our clients. It cover the functioning, installation, maintenance, features, and benefits of touchless bathroom faucets, addressing common concerns and inquiries that users have when considering this innovative technology.

Most Common FAQ

The most frequently asked questions (FAQ) regarding touchless bathroom faucets include:

- How does a touchless faucet work?

- What are the benefits of using touchless bathroom faucets?

- Are touchless faucets easy to install?

- How do I adjust the water temperature and flow on a touchless faucet?

- What kind of batteries do touchless faucets require?

- Can I manually override the touchless feature and use it as a regular faucet?

- Are touchless faucets reliable and long-lasting?

- How do touchless faucets help with water conservation?

- Can touchless faucets be installed in existing sinks or do I need to purchase a new one?

- Are touchless faucets more expensive than traditional faucets?

Providing valuable information to users looking to understand and make informed decisions about these convenient and hygienic devices. The most frequently asked questions (FAQ) regarding automatic soap dispensers include:

- How does an automatic soap dispenser work?

- What are the benefits of using an automatic soap dispenser?

- How do I refill the soap in an automatic dispenser?

- Are automatic soap dispensers easy to install?

- Can I use any type of liquid soap with an automatic dispenser?

- How long does the battery last in an automatic soap dispenser?

- Are there adjustable settings for soap dispensing amount?

- Can I use the dispenser for hand sanitizer or other liquids?

- Are automatic soap dispensers hygienic and reduce the spread of germs?

- Can I clean the dispenser, and how often should I do it?

These FAQs address common concerns and inquiries related to the functionality, installation, maintenance, compatibility, hygiene, and usage of automatic soap dispensers.

Related Articles Read:

Installation instructions ADA commercial motion sensor faucets

How to choose the best sensor faucet for your commercial use

Lavatory Commercial Sensor Faucets

Selecting the Right Motion Sensor Faucets For Your Sink

Browse Other Articles

Details: Junoshowers 67” Free Standing Acrylic Bathtub Floor Tub Filler

2024 Customer Review of Shower Mixer Valves

The Lazy DoctorSal Style Faucets

Types of Bathroom Faucets & Valves

How to Choose the Best Sensor Faucet for Your Commercial Project

Kraus Shower Set Installation Instructions

Best Matte Black Bathroom Fixtures Brands

Tools You Need for Installation

Best Smart and Digital Showers

5 Myths About Shower Wall Panels

Shower Massage Panels in Oil Rubbed Bronze Finish: The Sleek Look

Faucet Installation Instructions

What Are Eco-Friendly Shower Heads?

Selection & Installation Process for Bathroom Shower Fixtures

ADA Commercial Faucets and ADA Sensor Faucets: Best Savings

Bathroom with Dark Bronze Shower Heads